Flagstone Water Play Park

Project Overview

Opened in December 2019, the Flagstone Water Park is a ground-breaking design for the Flagstone development. This pivotal project not only highlights the unbound abilities of Playscape Creations design team but also showcases our in-house ability to bring these design ideas to life through engineering and construction.

Flagstone is part of the Logan City Council and is located 60km south-west of Brisbane’s CBD. The Flagstone Water Play Park is designed to be a destination park in this region and a beacon to both local residents and others that want to come and try it out, explore the area, and maybe even buy a home there.

Design, Engineering and Construction

In collaboration with the project’s stakeholders, our design teams came together to imagine an iconic waterpark; custom built to service the Flagstone Community, attract new families to the area and to create an ongoing community asset.

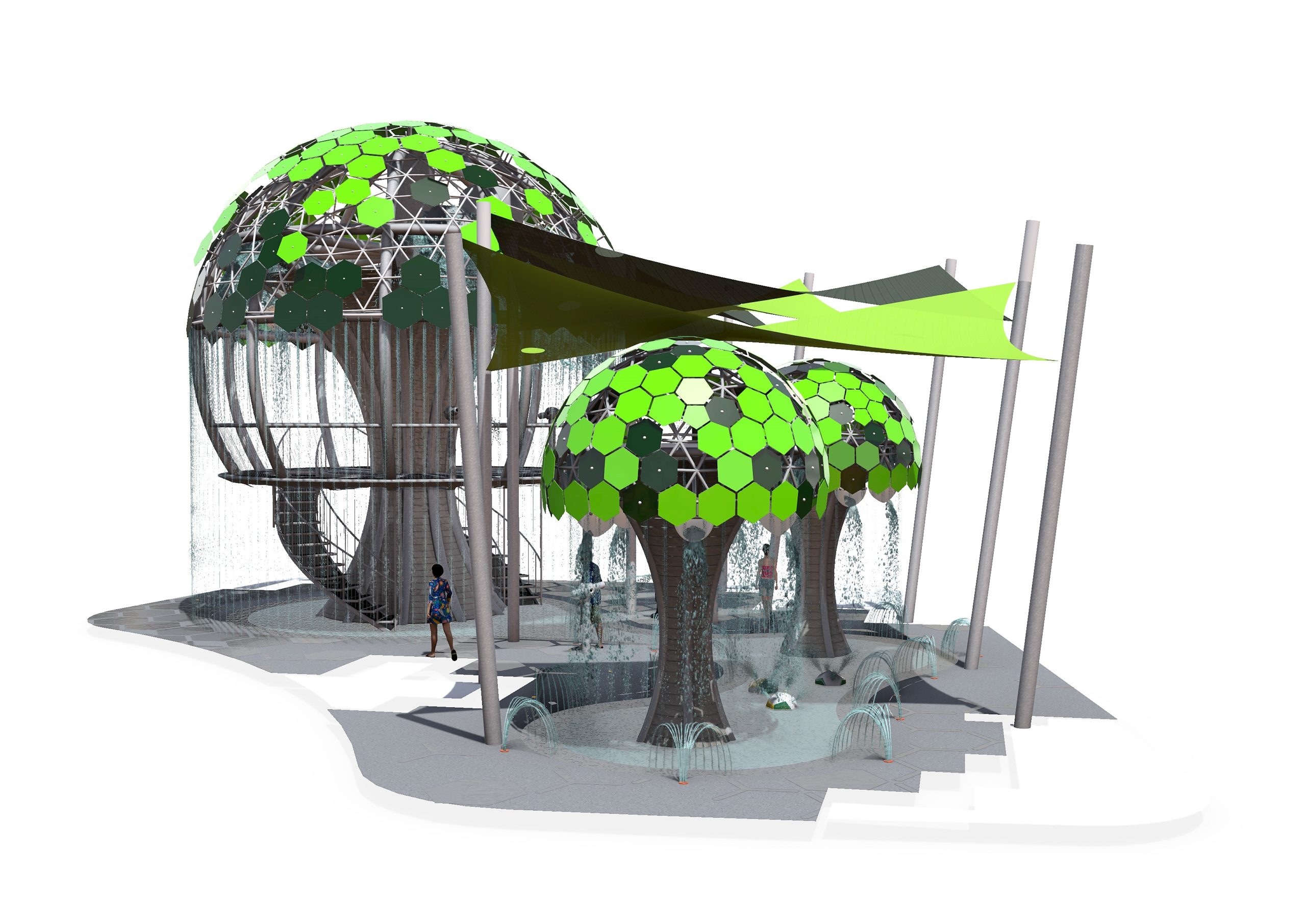

What came from these imagination sessions is a triple raintree; inspired by magical treehouses from our childhood and meeting children’s innate needs to climb, fantasise, socialise and play. Over 500 design hours brought this idea from the client’s vision to this concept, where almost infinite play opportunities for people of all ages have been packed into a small footprint.

Standing at over 10m high and reaching 10m wide, the central Raintree provides ample opportunities to explore and experience thrilling new heights. This massive multilevel structure is overflowing with fun including two intense dumping buckets, a rainfall curtain surrounding the canopy and water cannons to encourage multi-level play. A further two Raintrees decorate the site, providing quieter opportunities for younger children with cherry inspired tipping buckets and over 20 ground sprays.

It took more than 400 specialist engineering man-hours to design and develop the concept design into a workable model that could be constructed. A huge canopy layered with complex hexagons; intricate geometric mathematics and multiple 3D programs were utilised to create a roof structure capable of incorporating the hexagons, curved bars and node connections required to bear the structural and water loads of the completed raintrees. As a project that has never been built, we developed an ingenious one-point fixing method which allows the façade plates to be positioned and adjusted to create an interlocking structure over the dome.

In total, the roof structures of the raintrees contain more than 300 hexagonal facade plates and over 860 fixing bolts. Each piece was individually engineered, crafted and installed to fit perfectly over steel frame. Geotechnical conditions on-site required careful consideration throughout engineering, with screw piers placed strategically under the raintrees to accommodate the higher structural and hydraulic loads.

Fabrication and Construction

Fabrication of the raintree components and structural steel frames took over four months to complete off-site. Prior to delivery on-site, several non-destructive were conducted to ensure the structural integrity of every element and guarantee the pieces would fit together perfectly. All elements were then protected with a marine-grade three-coat paint system, ensuring ultimate longevity of the equipment.

Throughout the fabrication period, Playscape Creations completed all of the required civil works including 200m3 of bulk earthworks and installation of 98 screw piers to stabilise the site. To get the water flowing, over 10km of pipe runs were installed before the structural slab could be poured.

Over nine days, our construction team poured over 148m3 of concrete which made up the Flagstone’s waterplay slab, the central raintree support column and the surrounding footpaths and walkways.

Creating the central raintree in Flagstone’s brand new water park required a structural column to support the tree’s canopy and its 10 tonnes of steel. In two separate pours, our specialist subcontractors poured over 15m3 of concrete to form the structural column which stands at 9.0m in height and 1.2m in diameter. After a 14 day curing timeframe and engineering sign off, we could finally commence the intricate process of fitting the subframe to the column once piece at a time. A 90-tonne slew crane took care of the heavy lifting, however, the precision required to lift and align all of the individual pieces was staggering!

Once the canopy and tree subframe were complete, work began on installing the hexagonal façade plates; with 175 multi-coloured plates fitted to the central raintree alone!

Futurewood cladding adorns the base of the tree to resemble bark, which is low maintenance and a highly durable solution for a product that is constantly underwater.

To maintain water quality, high-tech specialist equipment is used to recirculate and save our precious water resources. All of the water used in the park is drained into underground balance tanks which then pass through an automatic filtration and sanitation system, ensuring only clean filtered water is delivered to the splash pad.